-

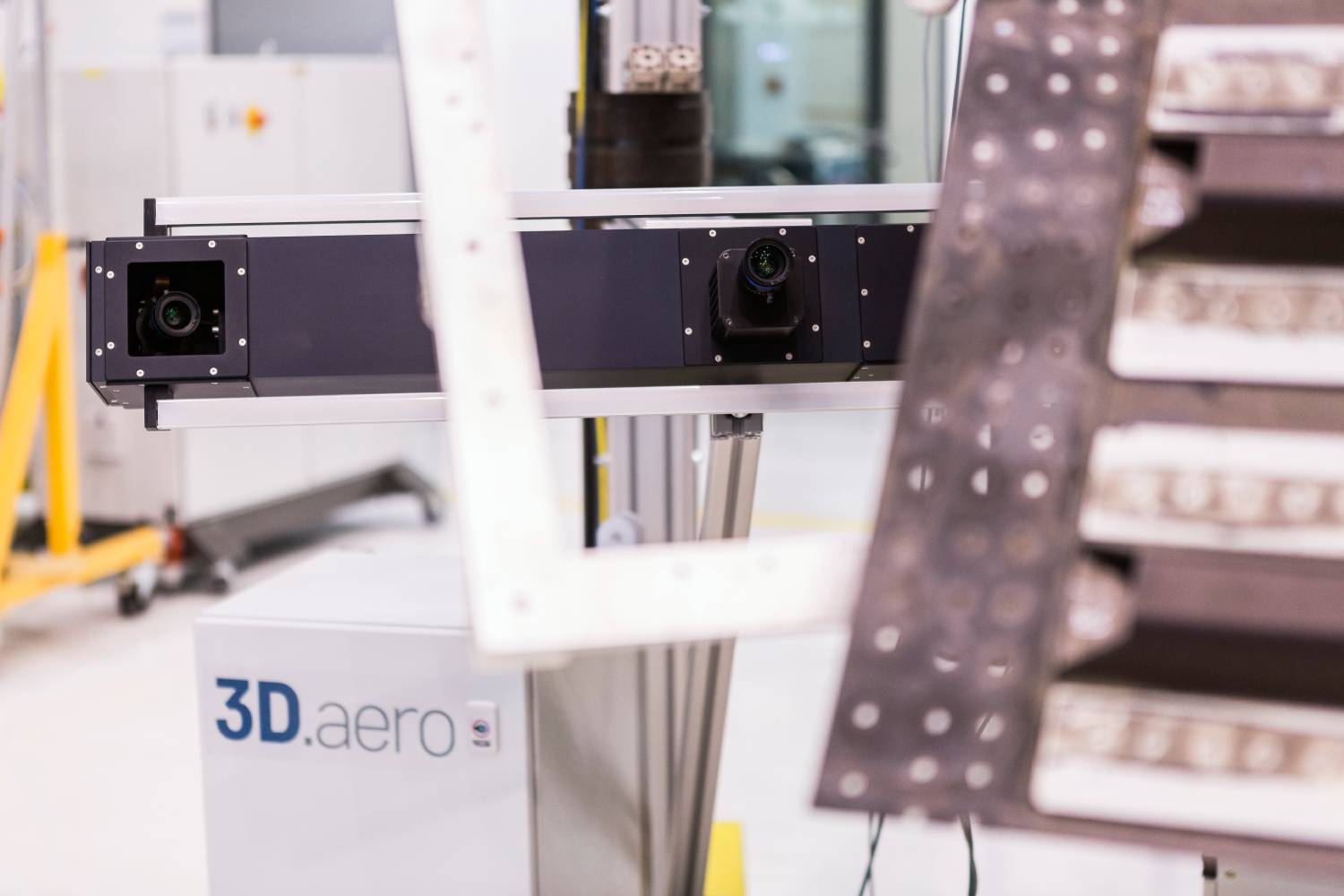

3D camera system for side shell measurement

With our solution for BiSconA, we are able to measure existing features on the shell surface with an absolute accuracy of less than 0.1 mm with respect to the build site coordinate system and also extract the interface edges into a 3D point cloud.

- Use of the 3D.SurfEyes Maxi sensor solution

- Precise 3D measurement technology

- Robust System

-

Thread testing by means of collaborative robot

Together with Lufthansa Technik, we have developed a collaborative robot system that can detect different thread inserts on complex components with the help of a 3D.SurfEyes Midi sensor. The result of the collaboration was a significant increase in the efficiency of the inspection process from 3 hours in the manual process to 4-5 minutes through automation.

- Use of the 3D.SurfEyes Midi sensor solution

- Collaborative robot for easy system integration and collaboration

- More precise examination due to highly accurate sensor technology

-

How robots help screw together compressor rotors

Together with MTU Aero Engines, we developed a robot solution that allows for complex screwing operations in hard-to-access areas. Our solution provides consistent prcision and therefore improves process reliability and efficiency, supporting the worker within the process.

- Development of an individual overall solution

- Precise detection and reliable processing

- Enables screwdriving work in hard-to-reach areas

-

ScanExpress: Making 3D scans of defects in engine parts

3D ScanExpress is a measurement system that can record, in three dimensions, damage to components that’s just 20 μm deep. This technology could soon be employed throughout MTU.

Interested? I am happy to be here for you!

"Get to know our practical and solution-oriented way of working, which starts with the uncomplicated testing of new ideas on a small scale and leads to the implementation of a certified automation solution."

– Michael Ernst, Sales Management

I look forward to the exchange!