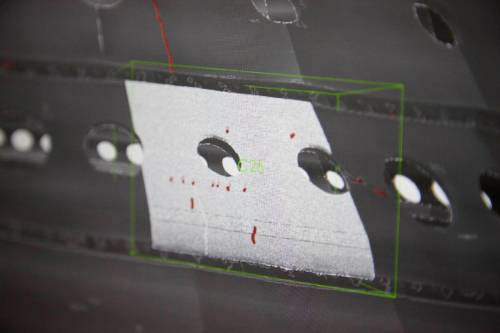

High Precision Surface Inspection

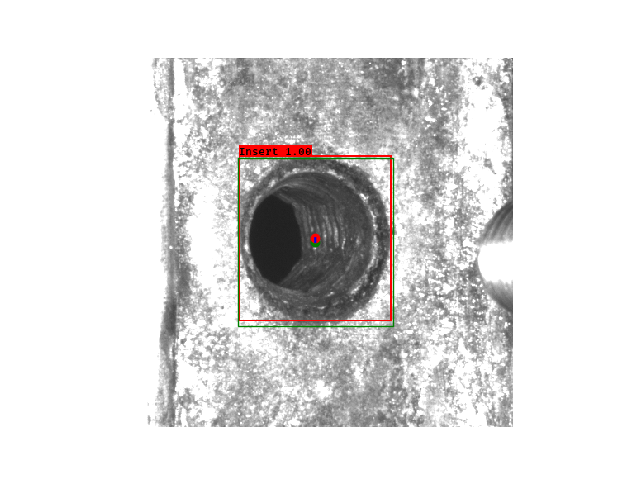

Detection, classification and measurement of surface anomalies in the µm range independent of color, structure or reflectivity in a fully automated setup or with operator support. In combination with our 3D.OS, the recorded surface information can be prepared, the relevant data extracted, processed and flexibly communicated to other processes or for documentation via different interfaces.

The inspection system solves a wide range of problems

- Crack inspection

- Defect identification

- Roughness measurement

- Borehole measurement

- Coverage test

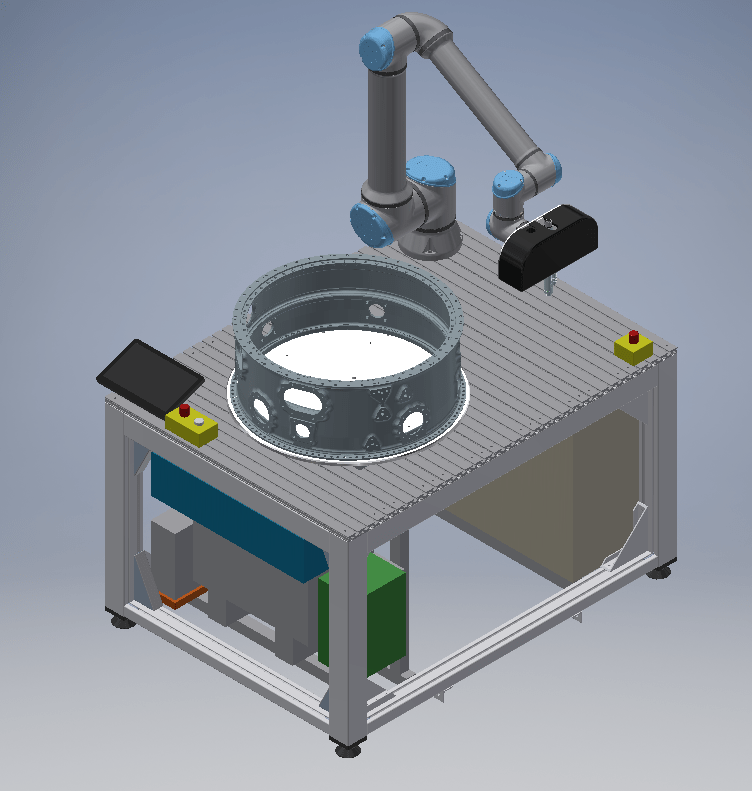

Fully automated robot-based crack inspection of engine parts

AutoInspect is the name of the system that performs a 100% inspection of combustion chamber components based on two industrial robots operating in parallel in combination with white light interferometers. Here, the degree of damage and the associated deformation of the component have no influence on the inspection result due to the adaptivity of the system. 75,000 individual images and 1.5 billion individual points are combined to form a model, which is examined for anomalies in parallel with the data acquisition. Detected anomalies are classified into damage classes using artificial intelligence. Cracks are then marked on the component using a robojet printer. The worker can look at any detected anomaly and adjust it if necessary.

Convince yourself of the extensive functions!

Convince yourself of the extensive functions!

High Precision Surface Inspection

Interested in our High Precision Surface Inspection?

Arrange an appointment

I look forward to the exchange!