HP-FX – Flexible

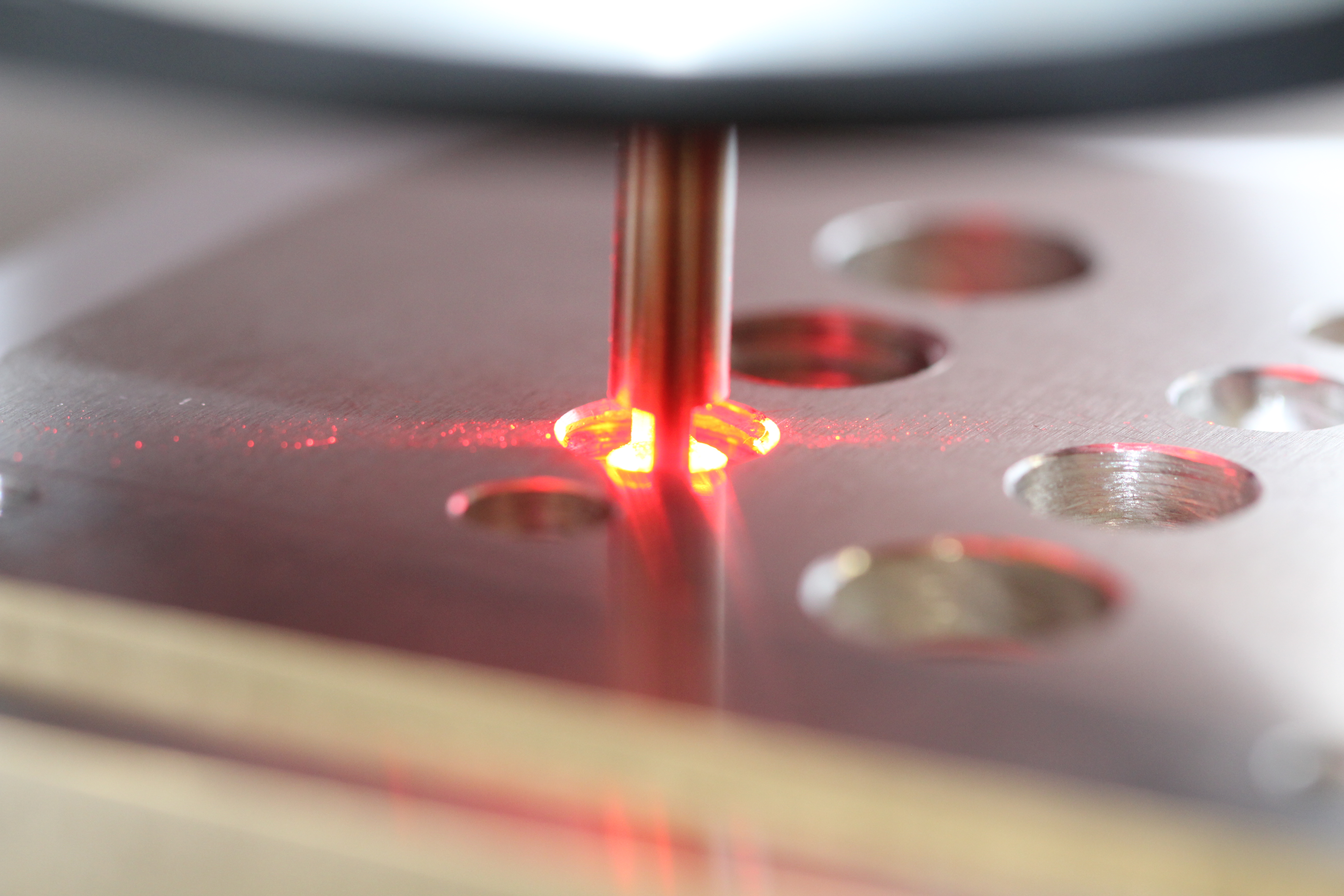

The combination of high-precision white-light interferometry and innovative cobot technology enables flexible handling and reliable damage inspection results on any conceivable component!

This makes high-precision digitizing of anomalies and defects a simplicity:

- Flexible handling and ease of use

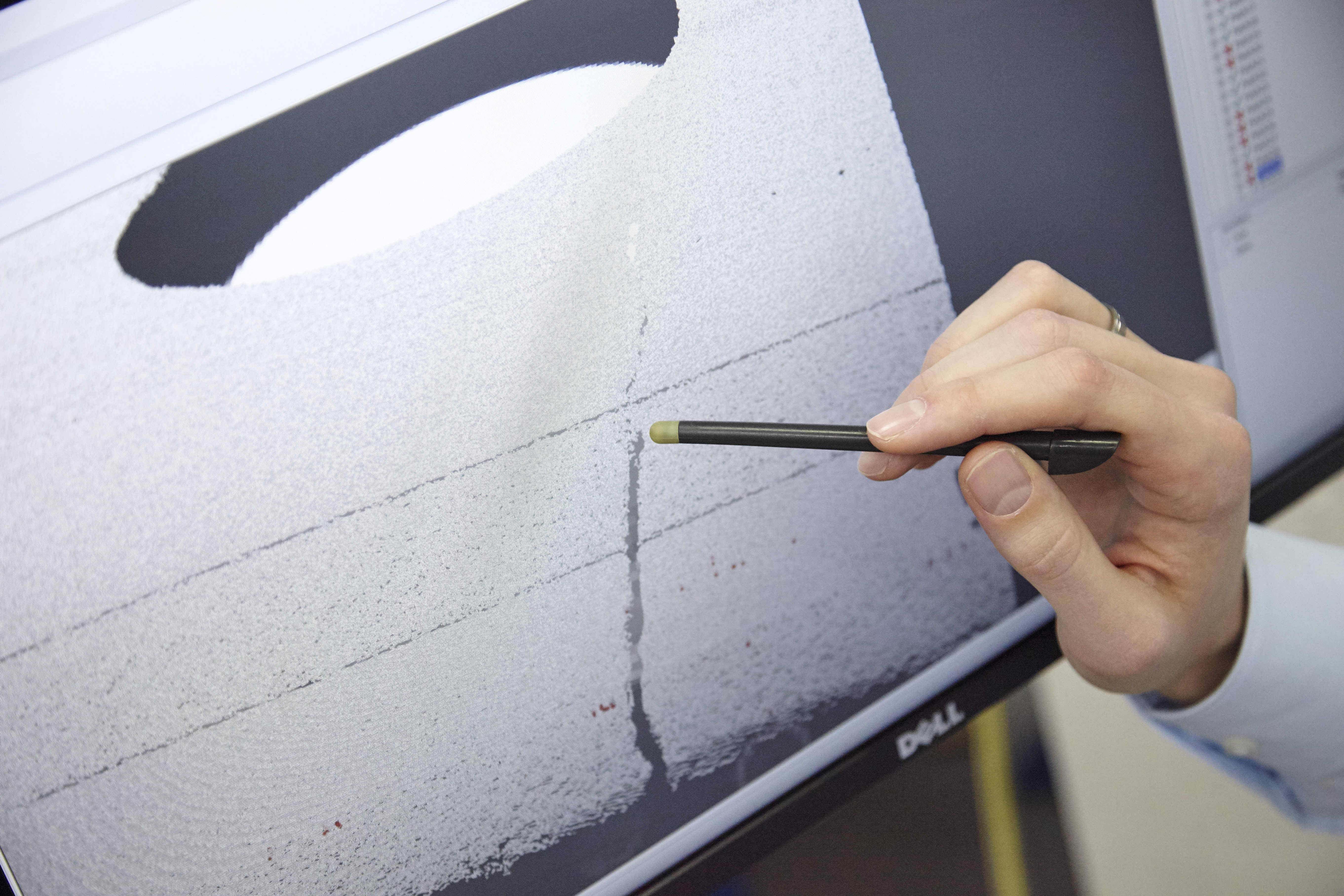

- Hand-guided or automatic execution of measurements on complex components

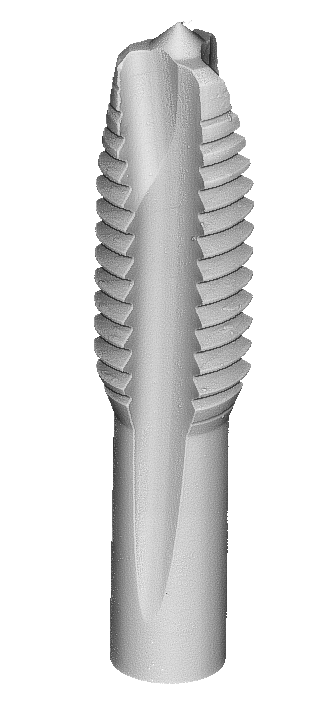

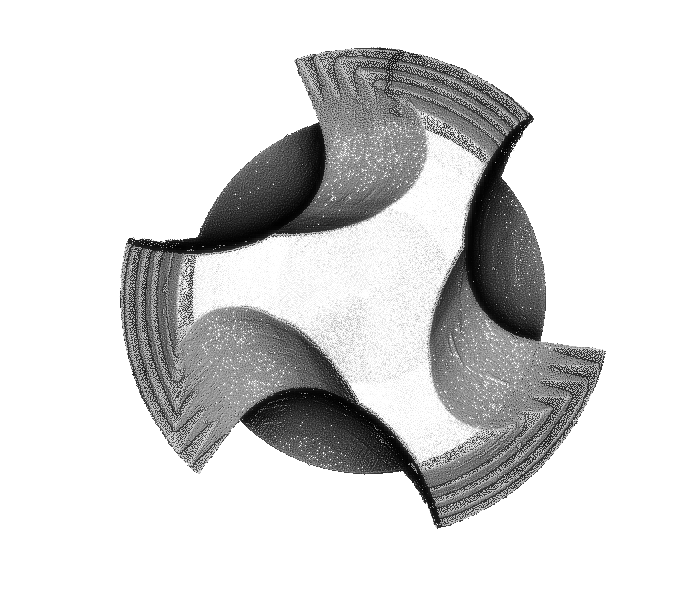

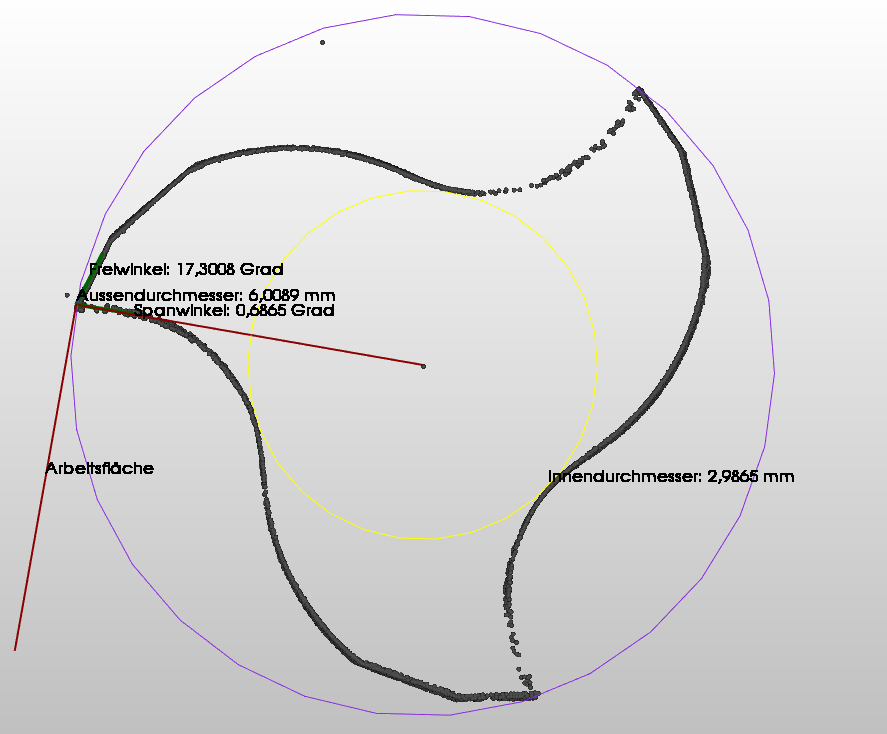

- 3D digitization of the component in µm resolution at the push of a button

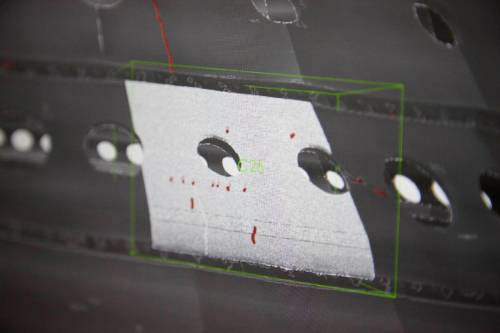

- Automatic identification and classification of damage and anomalies

Hand-guided or automatically operable with taught robot paths for repeat measurements.

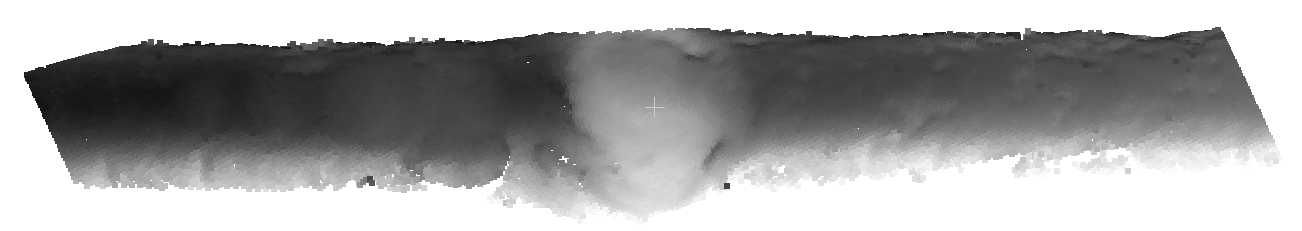

The HP-FX system can be used to solve a wide range of measurement tasks that require manual and easy handling in combination with highly accurate 3D data. With the HP-FD “DefectMeasurement” system, for example, defects on the component, such as scratches, dents, impacts, cracks or fractures can be measured and digitized locally with µm accuracy. The 3D images of the anomalies are then automatically evaluated, identified and classified to ensure a reliable inspection process. The HP-FC “CoverageCheck” optimizes otherwise manually performed measurement tasks on shot-peened components. The previously individually estimated degree of surface coverage can now be measured with high precision and determined automatically. This procedure increases process reliability and component quality enormously.