3D Position Detection

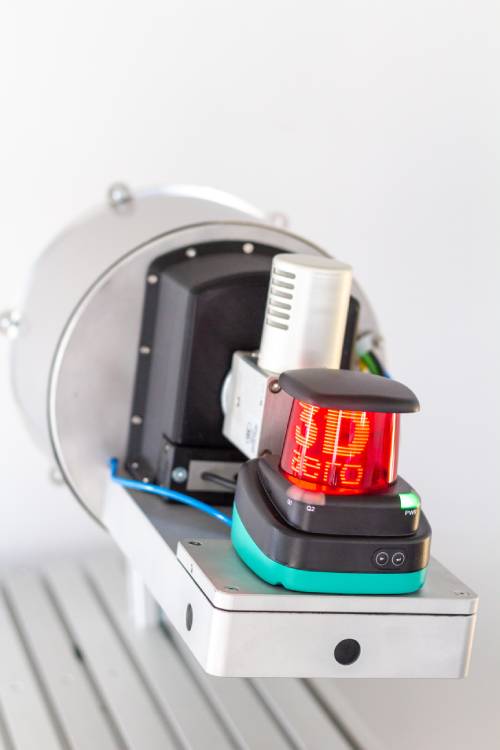

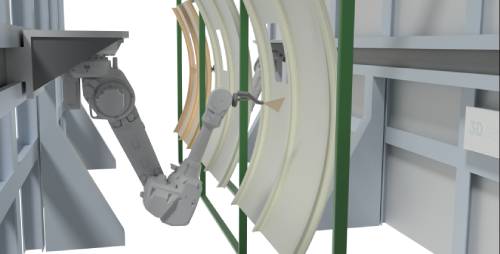

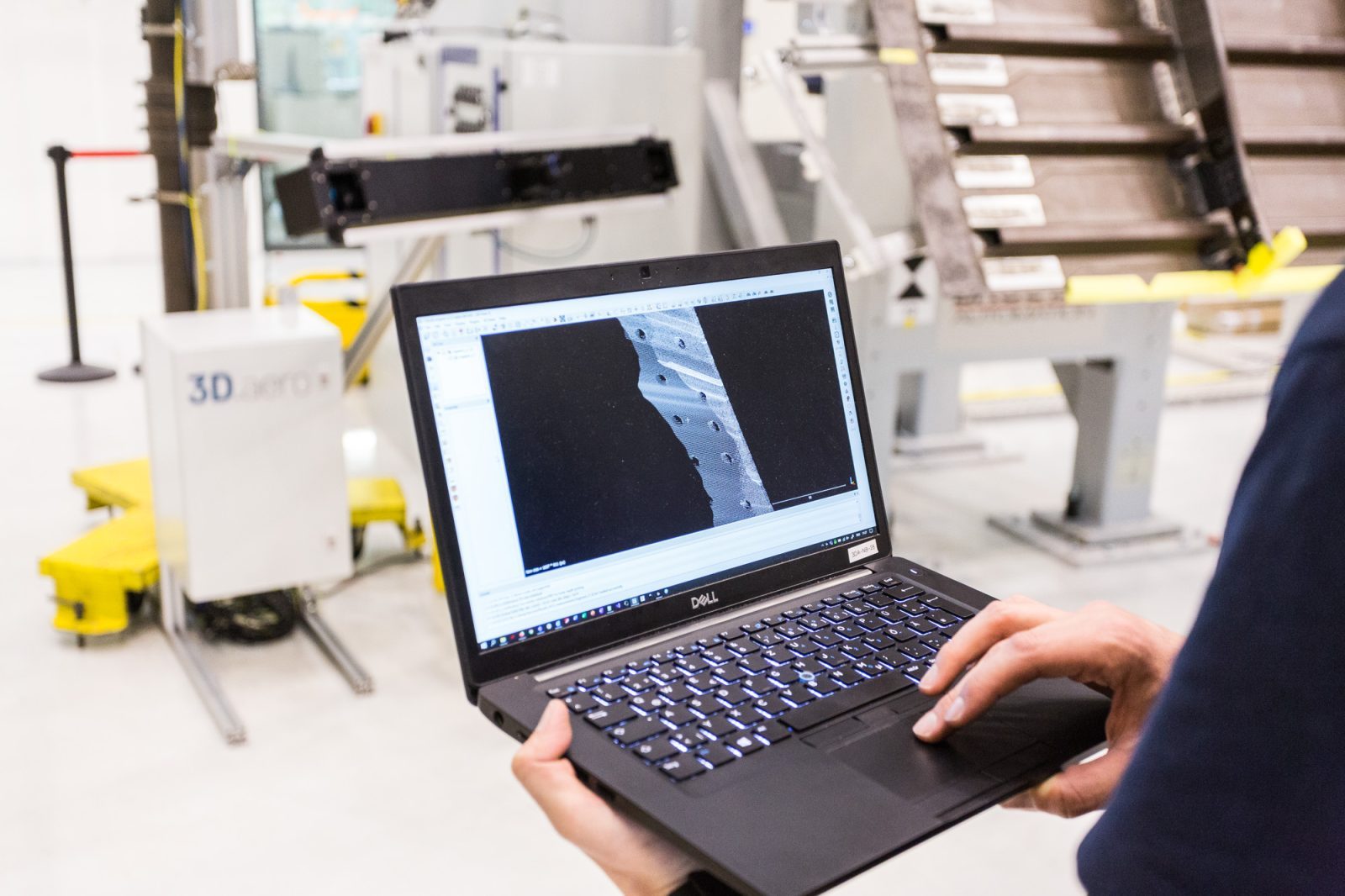

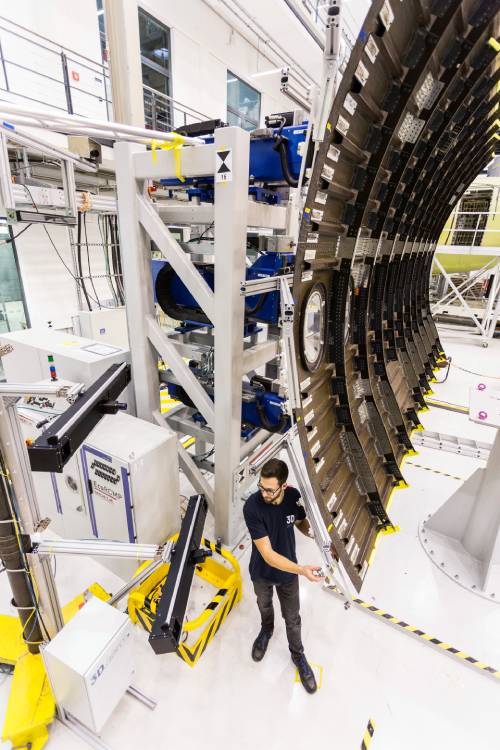

The perfect interaction of our 3D.OS software with the 3D.SwivelScan results in an innovative position detection and component identification system for a wide range of applications.

The system impresses with its high user-friendliness:

- Easy handling during commissioning and later production

- Uncomplicated integration of new components

- Even large components require only a few sensors

- Automatic position detection for the first time also for small and complex components

- ROS interface for manufacturer-independent application

World first for position detection in painting applications

The absolute measuring PXL+ sensor system with integrated color camera enables not only detailed 3D measurement but also advanced feature recognition via color contrasts. With the elimination of long calibration procedures or re-calibration when replacing sensors, as well as the simple addition of new components based on real measurement and ideal CAD data, the system trumps in its process reliability and efficiency.

Convince yourself of the comprehensive functions!

Convince yourself of the extensive functions!

Interested in our 3D Position Detection?

Arrange an appointment

I look forward to the exchange!