How can the aviation industry benefit from the use of artificial intelligence?

The answer is simple: In any possible way! Artificial Intelligence (AI) can be used for production and inspection purposes, as well as for worker support issues. Let us introduce you to the 3D.aero expertise of using AI.

Artificial Intelligence –

General Information

Artificial Intelligence can be used in many ways: for data processing, analytics, combinatory methods, …

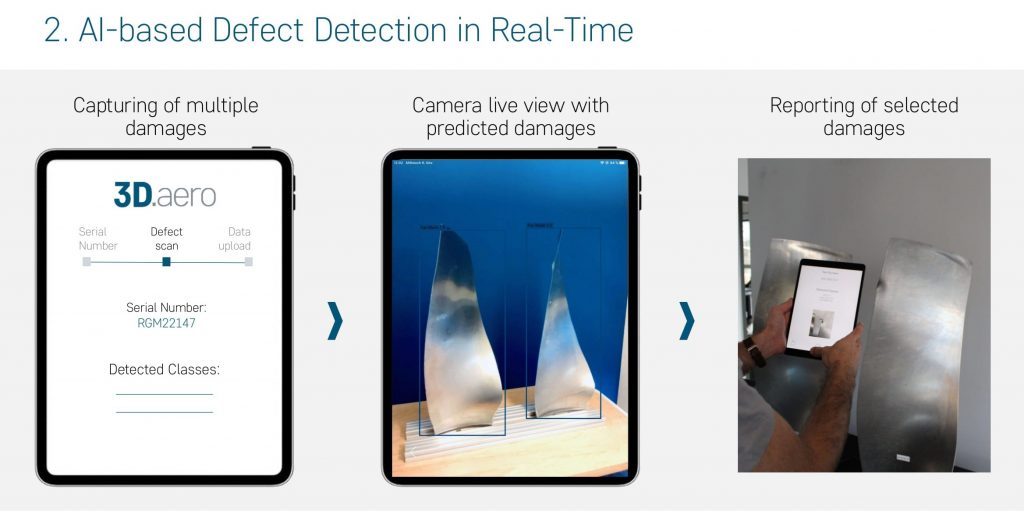

AI is a concept that stretches over any possible application field. In the field of automated inspection, there are some basic concepts that can be applied to accelerate and improve the process. For inspection purposes, it is possible to use Artificial Intelligence to detect cracks or dents in the workpiece automatically, which could take a human worker up to hours to inspect, while trying not to lose focus on the task. For this process, the concepts of classification and localization in AI can be used to ensure the function of this inspection system. Classification in this case means, that the AI can classify incoming surface data as intact or as different types of damages. The more different ‚damage‘ classes the AI learns, the more different cracks, dents, shape deformations and other damages, the system can detect. For this classification to function properly, the AI has to be taught many different shapes and damage types to learn every possible facet of a certain crack or dent to learn the fundamental features of a damage in order to distinguish between an intact or damaged object. This process is called ‚machine learning‘. Many different surface data measurements of damages have to be taught to the AI, for it to learn this classification behaviour in completion. There can always be more data to be gathered, because the more data the AI knows, the more certain it can classify these damage types.

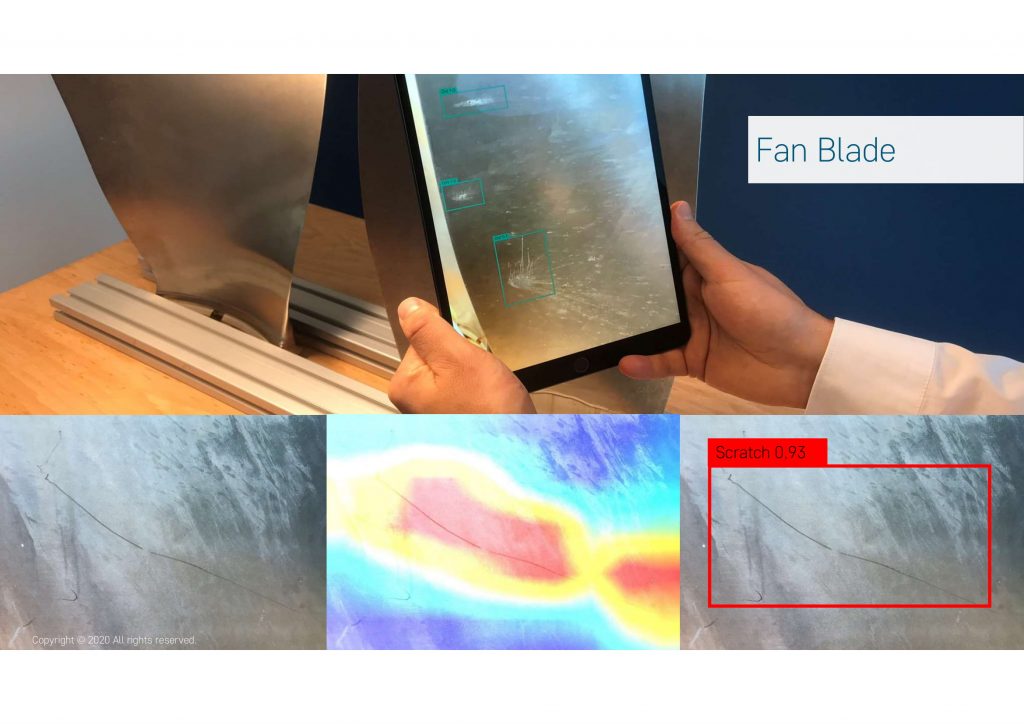

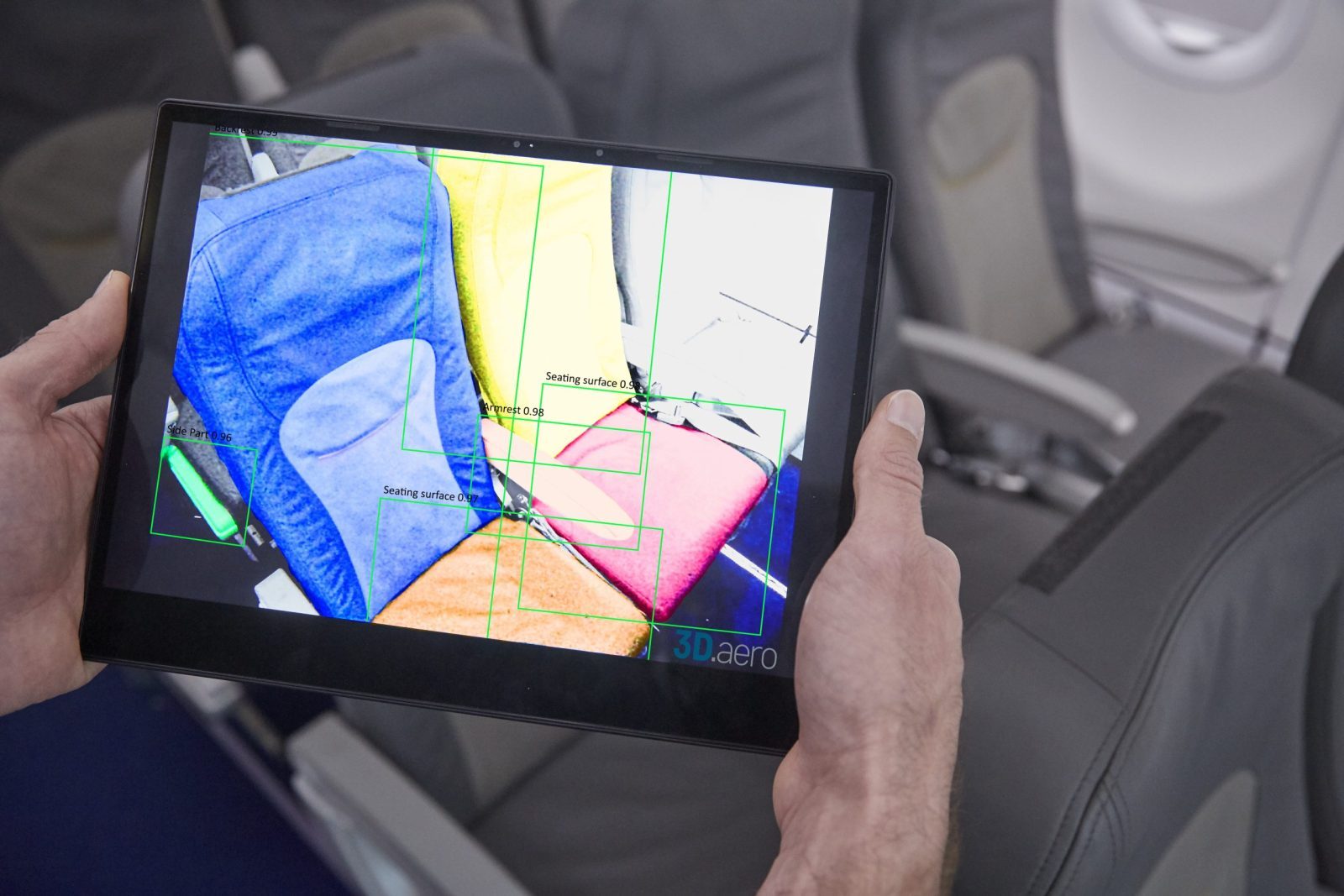

The other principle used is the concept of localization. This means, that the AI is able to detect its known damage types inside of a large 2D image. The AI has to learn, how to detect the damages in visual surface data or 2D projections of point clouds that are given to the AI program by the different measuring methods. If the data comes from either White Light Interferometry – a high precision 3D surface inspection method – or visual camera data, the AI can detect and show the position of damages on a connected screen. By combining these two concepts, the AI for inspection purposes can localize and classify any taught damage that occurs on the workpieces surface.

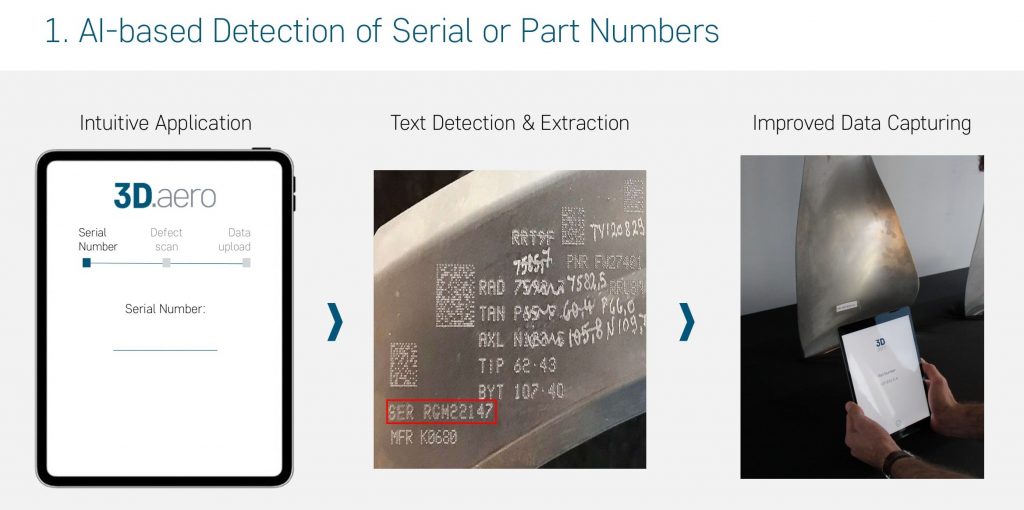

For a little extra usability, an AI can also be taught how to read texts on product labels via Optical Character Recognition. With this feature, all the information from the product label, like serial numbers and product names can be processed and digitalized together with the inspection data. We at 3D.aero also created a specialized neural network, that doesn’t only allow to read printed labels, but that can also process texts in any form on any surface. Whether it is handwritten, punched or milled in, the AI can read and digitalize each character correctly.

Specialties of the 3D.aero approach

We at 3D.aero use these advanced AI concepts to optimize the inspection and production processes in the aviation industry. Our expertise lies within the application of these systems to aviation parts and the usability within the hangar workspace. We use Artificial Intelligence for our AutoInspect system, on which you can find further information on our website. AutoInspect in general, is a robot-based system for crack detection in µm-resolution that is used for stationary inspection of aero engine parts. But the AI can also be used for the interactive Cobots, where robots work together with human workers on the shop floor. Here it is very important to have an integrated live tracking system of movement, so that the robot can interact with its surroundings in synchronization. If that would not be the case, the robot could hurt nearby workers or damage the workpiece by not adjusting to sudden movements. This feature is one of our many specialized applications for the usage of AI. You can also learn more about Cobots in our blogpost ‚Intelligent cobots on the shop floor‘. The newest and most innovative usage of AI here at 3D.aero, is our AI2Go system. Here, the process of damage detection and classification can be managed on an edge device such as a tablet or mobile phone. This mobilizes the process and makes it possible for a worker, who is already equipped with a mobile device, to assess anomalies in places that are not reachable for any shop floor robots.

In general, we at 3D.aero have the expertise to use AI in the aviation industry, while being able to use this technology on almost any possible device. Either mobile or stationary, our approach to using AI for inspection purposes makes us experts in damage detection and classification. All while making it possible to use the technology within the first steps of the systems installation. This enables a functional system early into the integration process, while constantly increasing the applications capabilities. However, we don’t let our AI algorithms lear and improve themselves during operation. For technical purposes in general and especially in aviation, reliability is key. Therefore we still require a human expert to assess new training data before updating the system.

These methods can be said to be the future of automated damage inspection, but they are already here today. In a following blogpost we will take a technological depp-dive into the process of creating and integrating an Artificial Intelligence into a system, to introduce you to the concept of UnderstandableAI.

Discussion of AI

Together with all of the positive points of AI we talked about in the previous paragraphs, it also has to be said that Artificial Intelligence is not a perfect solution to any given problem. AI is simply a tool to accelerate and enhance certain processes to help the worker complete a specific step of inspection or production faster and more reliable. For example, the AI used in AutoInspect mainly has the goal to reduce the numbers of false positives, where the classification system identifies an intact part of the workpiece as damaged. To reduce these false positives, the AI has to be taught many specific types of these possible misinterpretations in order to sort them out and not indetify those artefacts as damages. This process only makes the AI in this case usable and better than the manual inspection, because without an automatic detection and the sorting of these misinterpretations, a worker would have to select every false positive themselves and manually teach the program that a specific detected damage is, in fact no damage at all.

Also, if we compare the approach of classical image processing methods to the use of AI, is the AI really that much superior? In fact, the meaningful usage of Artificial Intelligence, like said before, only realtes to specific use-cases. It could be, that in many other applications, the installation and maintenace of such an AI-based inspection system might be even more cost- and time-consuming than just a simpler, classic approach. If the application doesn’t make sense for a specific use-case, it simply isn’t the superior way to use an AI. This can either be based on the effort of making the system work, or the general application field of the system in question. It should always be considered to upgrade an existing system with AI, but if it doesn’t improve the system for the specific case, it shouldn’t be integrated.

Another point to look at critically, is the data security of AI systems. If for example, a worker can be seen in the visual inspection data, what does the Ai do with this personal information? Should there be a tool to keep the workers anonymity safe? These are all questions that should be in mind, when thinking about the integration of AI into a system. In europe the GDPR (DSGVO) privacy protection rules are strict and one should always make sure that new technologies like AI follow these guidelines. It is very important to ensure privacy protection for everyone, which is why we at 3D.aero have ways to anonymize persons in pictures to make sure, the privacy right remain intact.

The theory of the Gartner Hype Cycle shows, how well a new technological accomplishment holds itself in the attention center of the public over time. In most cases, the attention steadily increases after a new technological discovery because of the new opportunities that come with it. The knowledge and usage of the new technology spreads widely into the public and in the industries. But after a specific time, the peak is reached and the attention starts lowering. Maybe because of new inventions, maybe because people discover that they cannot use the new technology for their own purposes, or because the new system can’t do what really was intended in the first place. Only after this low point, the industries that keep working on the system can understand and improve he application, after which the real productivity level off attention is set and steady. This also can be applied to the usage of Artificial Intelligence. We might actually be at the peak of the AI-usage attention all over the industries in the world. But only the industries – like us – that can adapt and improve the system, can reach the goal of improved productivity.

To conclude this discussion, it can be said that if the use-case is able to apply a functioning AI into its system, then this could possibly be a way to really improve the process. But this is not always the case. AI is a complex and powerful tool with many possible ways of functionality, but it has to be carefully thought of, before integrating AI into an existing system only because it is a current trend.

Do you have your own application in mind? Feel free to contact us!

As a joint venture between Luftfhansa Technik and Pepperl+Fuchs, we combine proven automation approaches with process know-how from the aviation industry and innovations such as AI and robotics to create advanced automation solutions. At 3D.aero, we also understand that the requirements and needs for technological solutions are as individual as the company and the processes and employees behind them. That is why we have made it to our mission to accompany our customers from the problem definition to the development of their own automation solution.

Contact us for further information. We are looking forward to your message!